Ralph C. Stiefel (1862-1938), a Swiss-born highly-educated engineer, arrived in the manufacturing center of Ellwood City, Pennsylvania, in 1894. He had come from England, where he had perfected a new method of piercing steel rods to make seamless tubes and pipes. Previous methods had featured flat sheets of steel being shaped into tubes and welded, but the welds would inevitably break under extreme pressure. Steel tubes were already widely utilized in the production of bicycles, and now mechanical tubes were in great demand with the advent of residential heating systems featuring boilers and radiators.

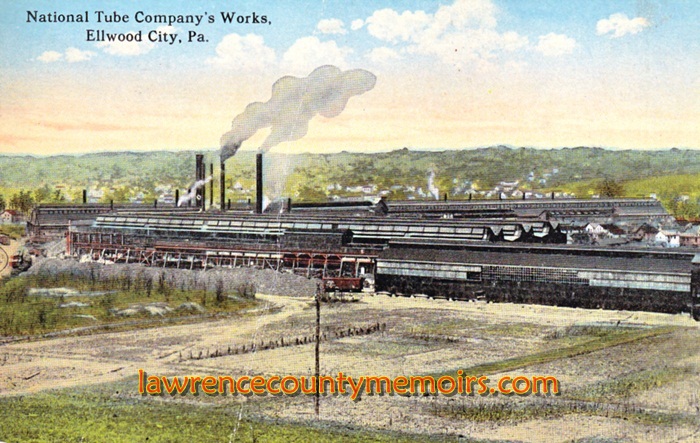

Stiefel found employment with the Ellwood Shafting & Tubing Company along Commercial Avenue, where he was made general manager of the plant and began producing his revolutionary seamless tubes. The company was soon sold to a group of Cleveland capitalists led by Henry A. Lozier (1843-1903), the “Bicycle King of America,” and renamed as the Ellwood Weldless Tube Company. In 1899, after the plant was acquired by the Shelby Steel Tube Company, Stiefel resigned and departed the company. By this time Stiefel, who had acquired great wealth and powerful allies, had became the leading citizen of Ellwood City.

Stiefel soon joined forces with several associates, primarily John H. Nicholson of Pittsburgh, and immediately went about forming a new company to be known as the Standard Seamless Tube Company. Property of less than three acres was purchased near the Burnstown area east of Ellwood City, along the road to Wurtemburg. A small plant was erected at that location beginning in late 1899 and went in production sometime in 1900. The upstart company specialized in making small tubes (two to four inches in diameter) for the boiler/radiator industry.

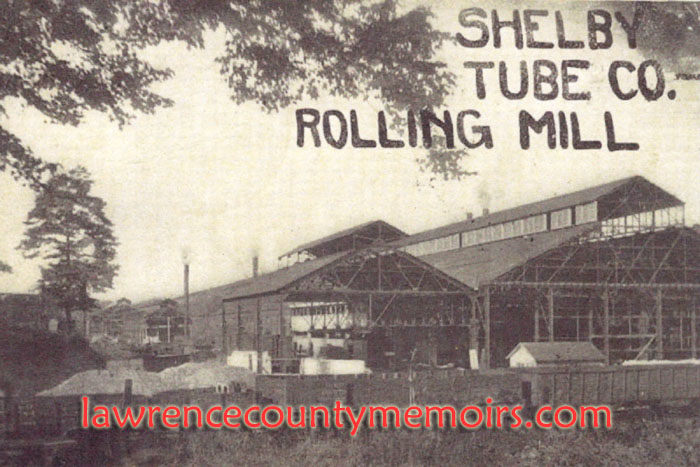

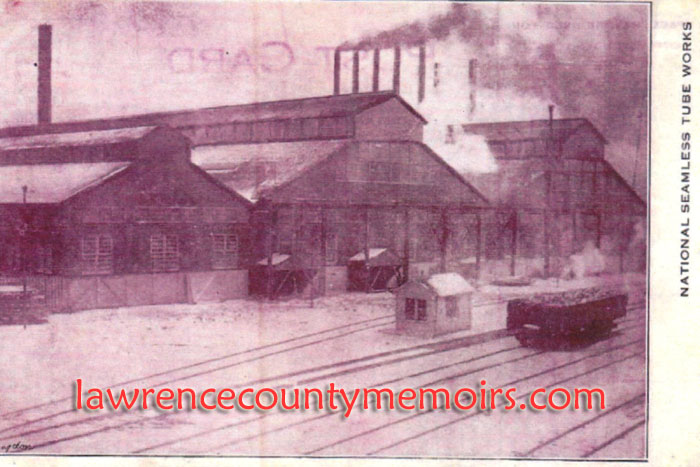

In early 1901 the company was involved in a series of mergers. It was initially sold to the National Tube Company, and soon after became involved in the mega-merger that created the U.S. Steel Corporation. After further reorganizations the plant (known as “Mill A”) came under the umbrella of the Shelby Tube Company, a division of U.S. Steel that encompassed many steel tube operations. The plants under Shelby’s control included the old Ellwood Weldless Tube Company (“Mill B”) and other facilities in Greenville, Pennsylvania, and Shelby, Ohio.

Company officials snapped up adjoining properties including a 50-acre site purchased in May 1906. The facilities of Mill A were greatly expanded, especially after the massive tube works at Shelby, Ohio, was lost to a devastating fire in July 1908. The so-called “Ellwood Works” benefited by being served by both the Baltimore & Ohio (B&O) and Pittsburgh & Lake Erie (P&LE) railroads. Business boomed and Ellwood City was soon recognized as the “Capital of the Seamless Tube Industry.”

The Ellwood Works underwent another large expansion during 1915-16 and the plant, known simply as the “Tube Mill” to local residents, eventually encompassed 127 acres. Mill B was closed in 1923 and its vital operations moved nearby to the Mill A site. The growing plant had no steel-making capabilities so it imported the raw materials (steel and iron rods) needed to production. A foundry department was erected at a later date. The massive facility eventually included its own hospital, fire department, social hall (Shelby Social Club), and in-house sports leagues.

Ellwood City owes much of its own growth to the success of the Tube Mill and the residential section known as Ewing Park is a direct result of the expansion of the company. As early as 1909 the company took an option on a large farmland property, located across the Connoquenessing Creek in Hazel Dell. A baseball field known as Shelby Field was constructed in 1909 and became very popular. In June 1918 the company formally purchased the property with the intention of building homes for its employees. The “Shelby Plan” was soon laid out and $800,000 was appropriated for the building of homes, apartments, streets, and a large bridge across the Connoquenessing Creek. The bridge and homes were mostly completed in 1919 and the area became known as Ewing Park. Ewing Park achieved borough status in 1924 and five years later was annexed to become the Fifth Ward of Ellwood City.

During World War II, when the massive plant was at its peak, it was Ellwood City’s largest employer with about 4,200 workers. The plant was geared towards war industry products and women were employed there in great numbers for the first time. After the war concluded the work force was dwindled down and returned to pre-war levels. In August 1946, in a stunning move, it was announced that the operations of the Ellwood Works would be phased out and relocated to Gary, Indiana, within the next few years. Fortunately for Ellwood City this planned move never took place. The plant remained in operation and was even expanded in 1959-1960.

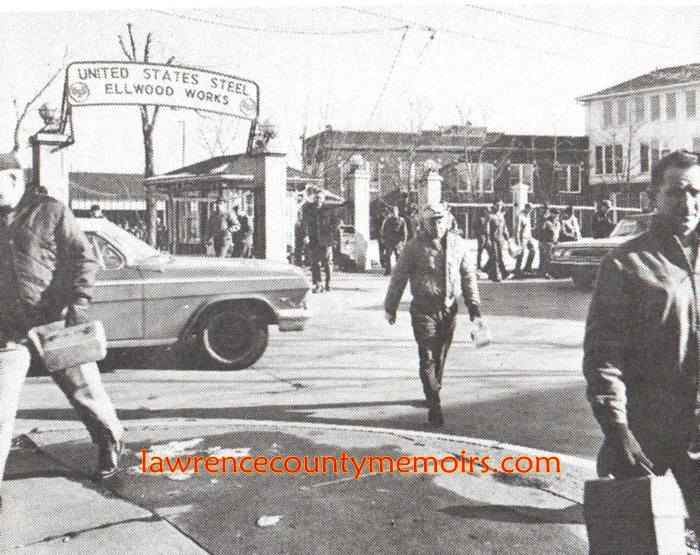

By the late 1960’s the steel industry began a steep decline due to low-cost foreign imports and other factors. In June 1970 the Tube Mill laid off 150 employees due to a lack of business. Further layoffs took place over the next few years. Finally, in late June 1974, it was announced that the Ellwood Works would be closed by the end of year as operations would be consolidated in Gary, Indiana. In the coming months the equipment and machinery of the plant was dismantled. The plant closed in January 1975 and its remaining 1,000 employees were all forced out of work. About half of them were eligible or authorized for retirement benefits, while a portion of the remainder were offered jobs in other plants in Pittsburgh or at Lorain, Ohio, or Gary, Indiana. The closing of the plant was a huge blow to the local economy. Among the men who retired at that time was my hardworking uncle George Migut, who had labored in the foundry for the last thirty years.

U.S. Steel officials provided assistance to help transform the site into the 92-acre U.S. Steel Industrial Park in a bid to lure future tenants. In June 1976 it was announced that a new outfit known as the International Metals Reclamation Company (INMETCO) planned to commence work on a new plant at the site in 1977. The recycling plant, designed to process metallic waste and dust from various steel factories into chrome and nickel alloy ingots, went into operation in mid-1978. Hall Industries Inc., which makes heavy equipment for the aviation, transit, transportation, and steel industries, also moved into the industrial park in 2002. Many of the old mills have since been torn down, but the once vibrant site is still alive – albeit on a smaller scale – with the sound of men hard at work.

The Standard Seamless Tube Company was founded in Ellwood City by Ralph Stiefel and associates in 1899. Stiefel prospered as his methods for producing seamless tubes revolutionized the entire industry. The plant was soon purchased by the National Tube Company, and then merged into the U.S. Steel Corporation, and eventually transformed into a massive Tube Mill operation. For a time Ellwood City was known as the “Capital of the Seamless Tube Industry.” (c1915) Full Size |

Several large mill buildings are shown under construction in the early days of the Tube Mill. (c1904) |

In 1901 the plant was part of a series of mergers and soon came under the control of the powerful U.S. Steel Corporation. (c1908) |

Ellwood City owes much of its own growth to the success of the Tube Mill, which was greatly expanded during 1915-16 and eventually encompassed 127 acres. During World War II, when the massive plant was at its peak, it was Ellwood City’s largest employer with about 4,200 workers. (c1914) Full Size |

Mill workers empty through the 1st Street gate after a day shift at the plant. It was a huge blow to the local economy when the Tube Mill was closed for good in early 1975. (c1970) Full Size |

A aerial view showing the massive size of the Tube Mill. The Connoquenessing Creek, the Portersville Road, and the Ewing Park Bridge can be seen at top of the photo. (c1965) Full Size |

The Tube Mill was founded in 1899-1900 as the Standard Seamless Tube Company on property of less than three acres near the Burnstown section of Ellwood City. It steadily grew into Ellwood City’s largest employer. (c1909) Full Size |

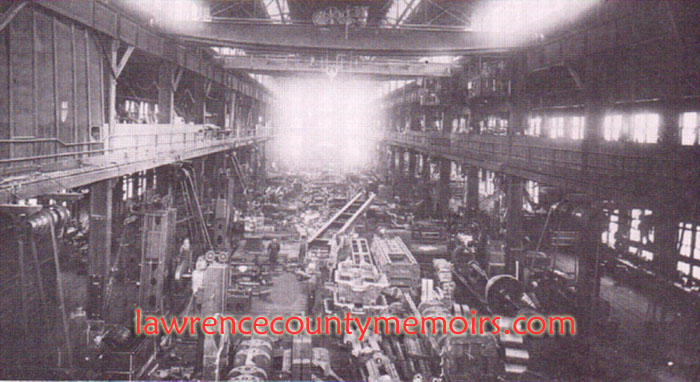

The inside of one of the massive mills in Ellwood City during World War II. (c1944) Full Size |

(Aug 2010) |  (Jul 2010) |

(Nov 2010) |

(Feb 2011) |

Comments

James G Houk #

Great Pictures. it would take a set of books to contain all the information about the Tube Mill. It had a wonderful history and tremendous effect on this area. I have a copy of the book Steel Town about the proposed closing of the mill.the Main gate would have made a great museum for the artifacts of the plant. Not too late to do that.

Janice Waller #

thanks for the information – found out my great grandfather worked here so was interesting to find out what the “tube mill” actually produced and the history of the company – thanks

Dale Perelman #

Are any of these pictures in the public domain? I might like to use one in an upcoming book on the steel industry.

Maryellen Carl #

I loved the pics and articles! My father, Oscar Lamenza, my uncles, and my grandfather all worked at National Tube!!

john prokovich #

my father retired after 34 years in 1963. dad bought a house on wood st ewing park.I left EC i 63 as was offered a job at st louis.

Rck #

My dad worked here during the war in the chem lab.

Alex #

Searching for information of Everette Austin Davis .He was a former worker at the National Tube Compagny in Ellwood City.

Enlisted in de Army on March 11,1943 (WW2)at Erie.

Sent to Europe and KIA 1944.

Adopted his grave at Us Cemetery at Margraten the Netherlands.

Anyone who can provide me with information or photo`s ?

Comment