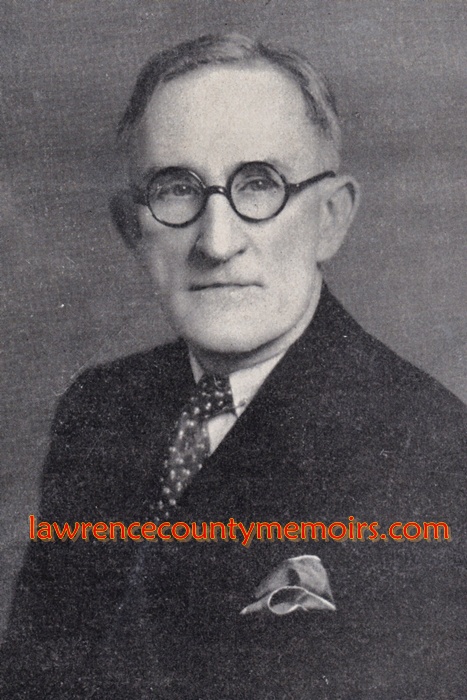

In early 1901 wealthy industrialist George W. Johnson (1847-1919) organized a group of investors in New Castle Pennsylvania, to establish the American Car and Ship Hardware Manufacturing Company. The aim of the company was to manufacture electrical supplies and metal alloy fittings for streetcars, trains, and ships. Johnson had recently been installed as president of the new Lawrence Savings and Trust Company, and many of the investors and directors were also associated with that prominent banking firm. The initiative wasn’t starting from the ground up as it had acquired the assets, equipment, and expertise of an existing company in Aberdeen, Maryland, which had recently shut down operations after a damaging fire.

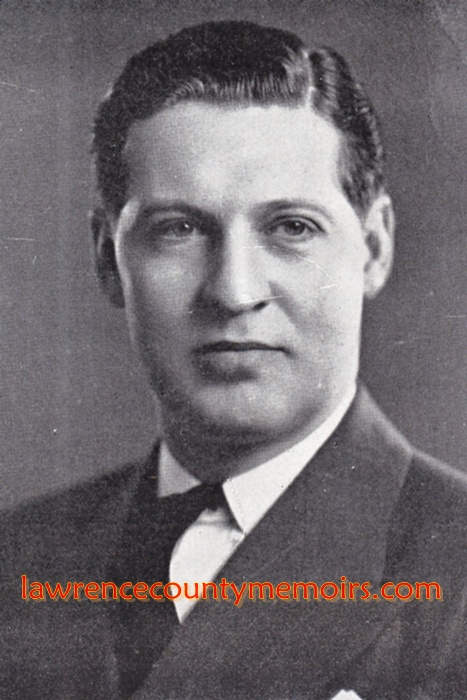

George W. Johnson, born in Mercer County, came to New Castle in about 1880 and made an immense fortune in the limestone and coal industries. His son Charles H. Johnson (1871-1918), who was married well-known philanthropist Grace Phillips Johnson, served as the first president of the American Car and Ship Hardware Manufacturing. This endeavor was a minor undertaking for the Johnson family, who were well-respected colleagues to internationally known steel executives such as Andrew Carnegie, Charles M. Schwab, and Elbert H. Gary.

~

A small factory was set up on Mechanic Street just west of South Mill Street. The New Castle Herald of Wednesday, June 12, 1901, reported, “The American Car & Ship Manufacturing company is about ready to begin operation in the building formerly occupied by the Keystone Plow company, which has been fitted up with the latest improved machinery. The principal articles which will be made by the new company will consist of electrical supplies and such hardware as is used in connection with this, such as handles for motors and brakes on street cars, etc.”

The New Castle News of Wednesday, June 26, 1901, reported, “Work in every department of the local plant of the American Car & Ship Hardware company was begun Tuesday. Within a few days a complete force will be at work in the place, and the plant will be on in full. When it is once fairly started there will be in the neighborhood of 100 persons employed in the plant. Many of these will be skilled workmen, some women and some boys. The majority of the skilled workmen employed at the electrical works at present were brought here from Aberdeen, Maryland, where the works were located immediately before coming to this city… There are few experienced men on the ground as compared with the many people who will have to be broken into the work. This will necessitate considerable delay.”

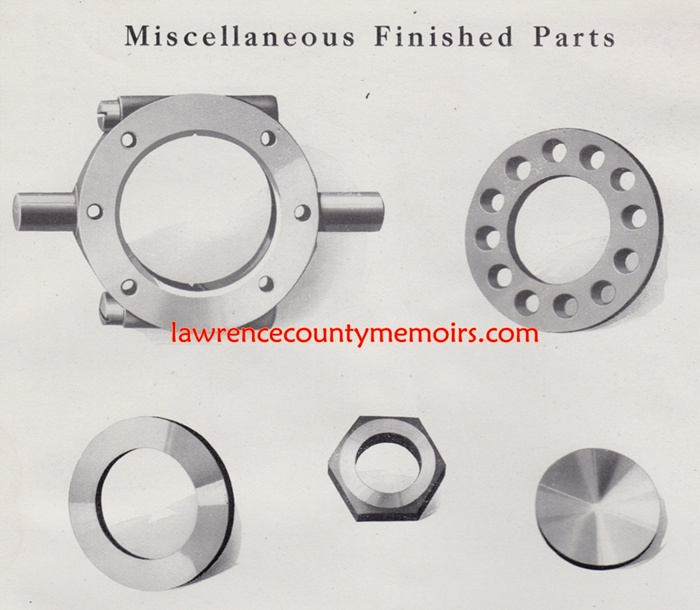

It seems the production of electrical products was soon phased out and the plant concentrated on manufacturing various brass and bronze (and later aluminum) fittings for trains and ships. It remained a steady, although unspectacular company over the next few years.

George W. Johnson made an extremely wise move in early 1909 when he hired Patrick “P.J.” Flaherty (1879-1948) as an accountant. Flaherty, born in Ireland but raised in Allegheny County, Pennsylvania, had been working as an accountant with the Pennsylvania Railroad Company (PRR). It wasn’t long before he was elevated to general manager of the American Car and Ship Hardware Company and was running the daily operations. Flaherty, recognizing an opportunity, started producing trimmings for the burgeoning automobile industry.

The New Castle News of Saturday, February 26, 1910, remarked, “Good business is assured at the plant of American Car & Ship Hardware company during the coming spring and summer, General Manager P. J. Flaherty stated to a News reporter this morning. During the past week the company has succeeded in landing a number of the largest orders for automobile trimmings that have ever been brought to the city… The new line of work which has been entered by this establishment has secured much more business than formerly and the capacity of the plant is soon to be tested. In may be that additional machinery and more room will be required… The name of the company may be changed from that of the American Car and Hardware company to that of the Art Brass company, but nothing has been decided upon.”

Flaherty had an idea to mass produce specialized parts for the auto industry. The company, while still making trimmings, shifted its production line and began making bushings and bearings for automobiles, farm equipment, and trains. Bronze, a metal alloy which contains small amounts of tin, was a preferred material because of its durability and ability to resist heat.

Flaherty undertook a trip to Muncie, Indiana, in 1912 to check out the local manufacturing plants. Indiana had a thriving automobile industry and was second only to Michigan. After a visit with the Muncie Products Company, which became a subsidiary of the General Motors Company, he returned home with an order for automobile bearings. Additional property was acquired along South Mill Street in connection with this effort and a large new machine shop was opened in May 1916.

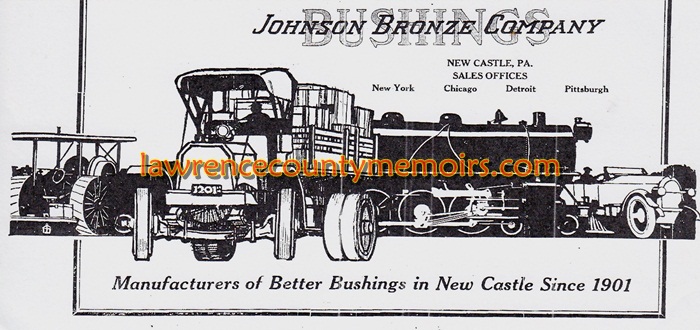

In January 1916 the company, employing 350 men working two 10-hour shifts, changed its name to the Johnson Bronze Company to better reflect its new direction. The New Castle News of Thursday, January 20, 1916, reported, “Owing to the entire change in the line of work now being done at the plant of the American Ship and Car Hardware company and the active interest being taken in that concern by George W. Johnson of this city, the name of the company has been changed to the Johnson Bronze company. This action was taken last week at a meeting of the board of directors and the new name has already been placed on the buildings of the company.”

During 1916-1917 the company underwent a major expansion and upgrade of its facilities along South Mill Street. This effort was timely because after the United States officially entered the Great War (World War I) in April 1917 the plant manufactured various products for the U.S. military. Before long sales offices were opened in Pittsburgh, Detroit, and New York.

In March 1917 the company made plans to commence with 24-hour operations to meet the increased demand. The New Castle News on Friday, March 23, 1917, remarked, “Another shift will mean the employment of 150 additional men, which will increase the number of employes of the plant to approximately 500 men. After April first, the same rate will be paid all of the men for their eight hour day, as is paid at the present time for ten hours. This action means about a 25 percent increase in the wages of the employes.” With 500 employees the Johnson Bronze Company was one of New Castle’s biggest manufacturers. In early 1918, with dozens of its skilled male employees serving in the military, the company began hiring women to work in its machine shops.

Charles H. Johnson served as president of Johnson Bronze until his untimely death, at the age of forty-eight, in December 1918. The elderly George W. Johnson took over as president, but he passed away less than a year later in October 1919. They were both laid to rest in the Johnson family plot at Oak Park Cemetery. Loyal executive P.J. Flaherty, who was previously made vice president, was appointed as the new president.

Success continued during the postwar period as the company, inundated with incoming orders, underwent major expansion efforts throughout the 1920’s. As the automobile industry took off so did Johnson Bronze. The first major addition took place in 1920-1921 when construction of several new modern brick buildings, all stocked with new equipment, was undertaken. Most of the old wooden buildings were replaced. The New Castle News of Monday, December 6, 1920, remarked, “At the present time, the bronze works are engaged in making the ordinary brass bushings that constitute a large part of their business while preparing to take care of the new babbit lined affair in the enlarged plant.”

Other additions were made in the next few years as business never seemed to falter. An editorial in the New Castle News of Friday, May 10, 1929, had this to say, “Every time I go down around the Johnson Bronze Company it seems as though they have added a new building. No sooner is one building completed than there is another one springing up, like mushrooms.”

It was also in January 1928 that P.J. Flaherty, who had been running the profitable company for over a decade, reached a deal with Grace Phillips Johnson and became the principal owner of Johnson Bronze. Grace Phillips Johnson, acting on behalf of the Johnson interests, recognized Flaherty was deserving of assuming ownership. The enterprising Flaherty, buoyed by a strong work ethic, went on became one of New Castle’s most influential industrialists, served on the board of directors for several local corporations, and supported various humanitarian causes throughout the city.

Flaherty guided the company throughout the good times of the 1920’s and into the tough times of the Great Depression. The New Castle News of Wednesday, January 22, 1930, reported, “P. J. Flaherty of the Johnson Bronze company said business has been slow but now is beginning to pick up. Orders have been coming in. Their business is affected by the automobile industry and with spring near and orders coming in Mr. Flaherty was optimistic with his views.”

In June 1931, Carnegie Tech graduate Louis R. Sandler (1893-1982), who joined the company in 1917 as an metallurgical engineer, was made vice president and special assistant to P.J. Flaherty. At that same time Flaherty’s oldest son, J. Preston “J.P.” Flaherty (1904-1968), a 1929 Yale graduate, was made head of all accounting departments and began working his way up the corporate ladder. His two other sons, Joseph F. Flaherty (1909-1975) and Edward M. Flaherty (1911-1972), would also join the company.

Johnson Bronze had always been operated as an “open shop,” but in 1933 representaives of the Local No. 92 of the International Brotherhood of Foundry Employees (IBFE) began organizing the workers to join the union. Tensions began to flare in early 1934, but not over increased wages or less working hours. According to the union representatives, company officals, including P.J. Flaherty, were unwilling to recognize the union and even refused to meet for discussions.

On Monday, May 28, 1934, while Flaherty was in Detroit securing contracts, the workforce went on strike. A minimal crew of strikebreakers kept the plant going, but violence soon eupted along South Mill Street. A bitter back and forth battle was carried out in front of the plant and in the newspapers, but cooler heads soon prevailed. The strike was settled on Tuesday, June 19, 1934, when a large group of employees returned to work. Both sides compromised but each claimed victory. Johnson Bronze officially remained an open shop, but Flaherty announced he would recognize the union and those it representated.

In the early 1940’s, with active hostilities raging in Europe and the Pacific Ocean, the United States was doing its best to remain officially neutral. With war inevitable most major factories and plants were geared towards supplying products to our allies as part of the Lend-Lease Act of March 1941. After the surprise Japanese attack on Pearl Harbor, Hawaii, and nearby airbases on December 7, 1941, the federal government ramped up its production efforts and factories across the nation were converted to assist in the massive U.S. military effort to defeat Germany and Japan.

Johnson Bronze didn’t have to undergo much transition as its sleeve bearings had been used in military aircraft, ships, and tanks for several years. In conjunction with the wartime training program going on at the Trade School at Ben Franklin Junior High School, hundreds of women went on to take additional hands-on training sessions at Johnson Bronze. Female labor became vital as many male employees were off serving in the military. Another major expansion effort was undertaken during the 1940’s.

In July 1942, as union activity was once again elevated, an agreement was reached between employee representatives and company officials to officially recognize the new Bronze Workers Independent Union (BWIU), an organization unaffiliated with any established union.

In February 1943 the National Labor Relations Board (NLRB), responsible for enforcing federal labor laws, held a hearing in New Castle charging Johnson Bronze officials with attempting to restrain union activity in the plant. The charges involved possible suppression of Local No. 69 of the United Automobile, Aircraft and Agricultural Workers of America (UAW) of the Congress of Industrial Organizations (CIO), of which a handful of plant workers belonged to, and illegal influence within the BWIU. Johnson Bronze officials and BWIU representatives denied the allegations during the ten-day hearing held in the Lawrence County Court House. In April 1945 the NLRB ordered that the BWIU be dissolved and that Johnson Bronze officials should recognize any other unions that garnered significant employee membership. The company refused to adhere to the order and the case became bogged down in the federal court system.

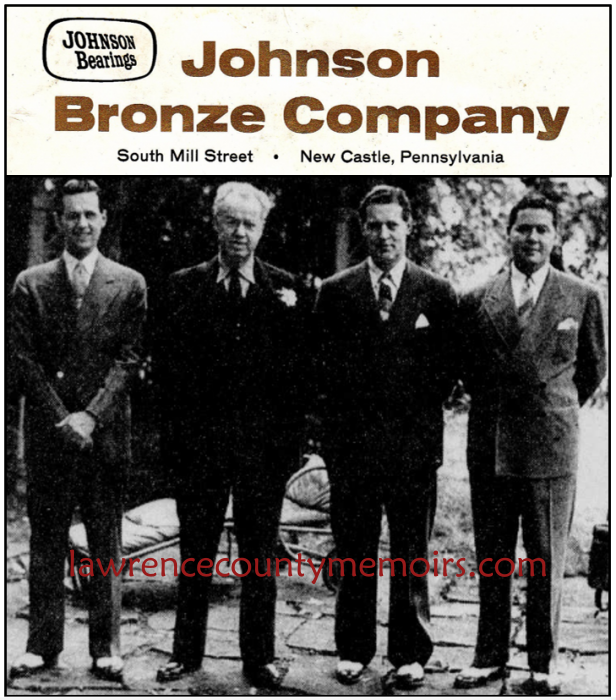

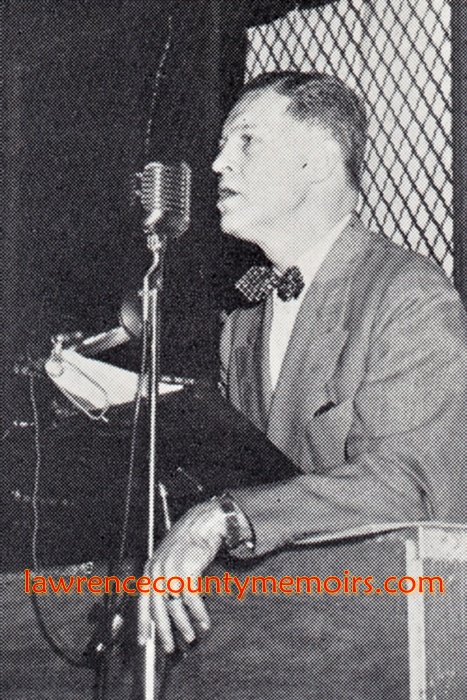

In June 1943 the two plants of the Somerville Iron Works, in Somerville, New Jersey, and Chattanooga, Tennessee, which P.J. Flaherty had previous dealings, were officially absorbed into the Johnson Bronze fold. They would continue to operate with their established names. At the same time, it was announced that Flaherty, reducing his active role with the company, was stepping down as President and becoming Chairman of the Board of Trustees. He was succeeded as president by the oldest of his three sons, J.P. Flaherty. Other officers included vice presidents included Louis Sandler and his other sons Edward M. Flaherty and Joseph F. Flaherty.

In January 1945, the NLRB hosted an election of about 1,300 eligible (non-supervisory) Johnson Bronze employees to determine if they should join an established union. The majority, 761 employees, voted to join Local No. 69 of the UAW-CIO. The New Castle News of Tuesday, April 10, 1945, reported, “Local 69 of the UAW-CIO has been designated as the official bargaining agent of all production and maintenance employes of the Johnson Bronze company by the panel of the Regional War Labor Board, which met at the Roosevelt Hotel, Pittsburgh, April 5, according to Rueben Peters, representative of the United Auto Workers. The CIO union had been chosen as the bargaining agent by a vote of almost two to one last January, but the company felt that it was obliged to deal with the independent Bronze Workers Union, according to Mr. Peters… The panel unanimously recommended the Regional WLB to direct the disputing parties to proceed immediately to negotiate the terms of a collective bargaining agreement.”

In October 1945, as World War II was winding down, the employees of Johnson Bronze, represented by Local No. 69 of the United Automobile, Aircraft, and Agricultural Implement Workers of America (UAW-CIO), were close to going on strike. They wanted a wage scale that was similar to workers employed in “Big Steel.” A compromise was reached, and the employees were granted a wage increase and the plant was recognized as a union shop. The work week was reduced to forty-five hours, time and a half was granted for any work over eight hours and all day on Saturdays, and double time was approved for Sundays and holidays. The agreement ended several years of dispute between multiple parties.

Within a few years the company lost its longtime patriarch as the elderly P.J. Flaherty passed away rather suddenly at the age of seventy in February 1948. Flaherty, who was spending time in Palm Beach, Florida, grew ill and was hospitalized in Miami. He died soon after due to complications of a broken blood vessel. The New Castle News of Friday, February 13, 1948, remarked, “The announcement of his death came as a shock to the entire city… His death removes a positive force in New Castle. Successful in his own business he lent his genius to every worthwhile civic activity here. More than one organization in New Castle owes its present sound financial structure to his ability and his willingness to aid.”

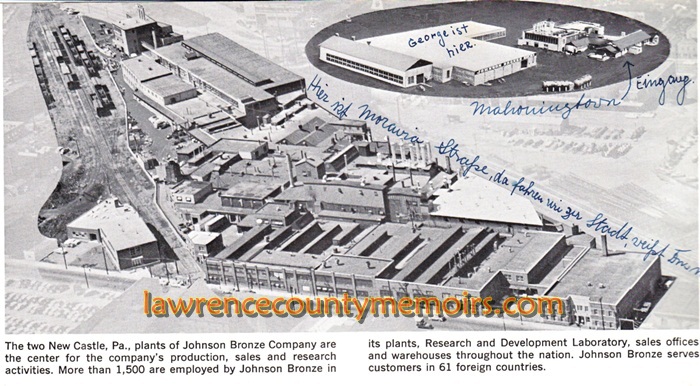

By the late 1940’s the company had about thirty warehouses or sales offices throughout the country with about 1,200 total employees. The property along South Mill Street was built to capacity and additional space was needed. In early 1951 the company purchased the former foundry of the Bowman Construction Company, closed in late 1945, along Mahoning Avenue in Mahoningtown. The existing two buildings on the six-acre site were renovated, and additional facilities were erected. In January 1952 the plant went in operation where a new process for making machined bronze bars got underway. In May 1955 J. Preston Flaherty ascended to the position of Chairman of the Board and his younger brother Edward M. Flaherty, a highly educated lawyer and longtime executive with the company, took over as President. Youngest brother Joseph F. Flaherty was also representing Johnson Bronze out of its office in Detroit, Michigan – where he had direct liaison with the automobile industry. Both younger brothers were graduates of Georgetown University.

The company continued to thrive and opened a modern Research Lab on South Mill Street in early 1959 and established a subsidiary in Salem, Indiana, known as Ferraloy Corporation in 1960. They also opened two international subsidiaries in South America known as Johnson Bronze de Brazil in Rio de Janeiro, Brazil, and Sintermetal S.A. in Buenos Aires, Argentina, and had an interest in Nagato Metals in Tokyo, Japan. At its peak the company employed about 1,600 workers in New Castle and around the country.

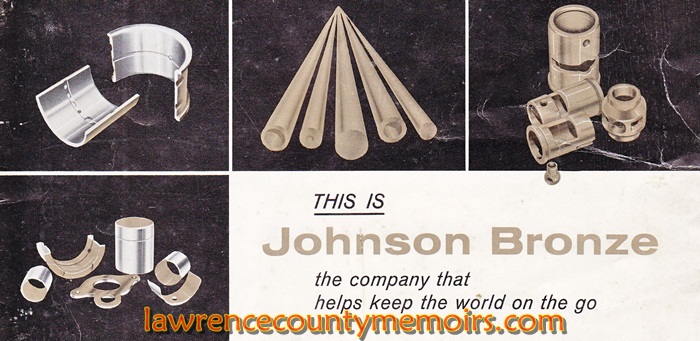

An article in the New Castle News of Tuesday, January 26, 1965, best describes the company’s product line, “The Johnson Bronze Co. prides itself on being able to a make a bearing for any moving part. In fact, there is no other single sleeve bearing manufacturer in the entire world which manufactures as complete a line of sleeve bearings, bushings and bearing materials as does Johnson Bronze.” The outfit sold fittings to an endless list of major players such as the Ford Motor Company, General Motors, Chrysler Corporation, Mack Trucks, John Deere, Caterpillar Tractor, International Harvester, General Electric, and the Westinghouse Electric.

Johnson Bronze, which had experienced significant growth throughout its existence, began facing some internal and economic difficulties in the late 1960’s. The employees, down to about 600 from the peak of 1,600, went out on strike in September 1967, but returned to work seven weeks later with better pay and increased benefits. In January 1968 the Chairman of the Board, J. Preston Flaherty, so influential in the expansion during the 1950’s, passed away at the age of sixty-three.

In September 1968, after decades of Flaherty family ownership, the Johnson Bronze Company and its associated firms were sold to Waltham Precision Instruments Inc. of Massachusetts. Charles H. Schubert was brought in from Connecticut to serve as the new president. Edward Flaherty stayed on as the new chairman of the board until stepping down two years later. Unfortunately, he also passed away at the young age of sixty in June 1972. All the goodwill that the Flaherty family had built up with in the preceding years would be lost in the coming two decades.

Johnson Bronze, with about 500 employees in New Castle, continued in operation under new ownership but faced increasingly problematic labor issues during the 1970’s. Another strike commenced in September 1976 and shut down production for over four months. The company began threatening to close the plant and announced in September 1977 – the same month that Youngstown Sheet & Tube abruptly shut down in nearby Ohio – that it would be relocating some of its local operations to a newly acquired site in Summerville, South Carolina. The move began in April 1978 and cost 150 employees in New Castle their jobs.

At the end of the workday on Thursday, July 3, 1980, the 220 remaining employees, most who had seniority with the company, were unexpectedly laid off. The move was in direct correlation to Caterpillar Corporation on Peoria, Illinois, a major customer of Johnson Bronze, announcing major layoffs. A handful of employees were retained to keep the plant in working condition. Robert H. Morris, the chairman of the board announced the plant would be indefinitely closed until economic conditions improved.

About six weeks later the Johnson Bronze Company filed for federal bankruptcy protection and officials began meeting with creditors to attempt to save the firm. The New Castle News of Wednesday, August 20, 1980, quoted Chairman of the Board Morris with, “The purpose of this action is to save jobs for the employees and the community. It is the intent of the company to resume operations as its reorganization permits.”

In January 1981 an investor group, led by New York attorney Joel Eric Cooper, acquired a majority share of the company and began an effort to revitalize it. Cooper became CEO while Morris remained as chairman of the board. The risky plan called for the sale of the Summerville property and other assets to pay back creditors. A small group of laid-off employees were called back to work in February 1981 as several orders for parts were received. Cooper also offered to purchase the nearby Mesta Machine plant, closed due to strike, for $15 million, but was rebuffed. Meanwhile, Cooper, facing an uphill battle, met with prospective buyers and attempted to sell the Johnson Bronze plant.

On Friday, August 7, 1981, the plant was shuttered for the last time. Johnson Bronze’s proud history as an industrial giant in New Castle came to an end after eighty years. This was part of multiple local closures to include the Pentax Foundry (June 1981), Rockwell International (May 1982), and Mesta Machine (June 1982). The economic situation in New Castle in the early 1980’s was certainly bleak.

In late October 1981 a four-day auction was held to sell off the contents of the plant. The 13.87-acre property, a few of which were previously owned by CSX railroad, was soon put up for sale. In January 1982 the federal bankruptcy court accepted the bid of $300,000 from Robert A. Frank. Frank soon transferred ownership to the Bertin Realty Company, owned by himself and Bernard W. D’Ambrosi. Before too long the city took measures to seize and sale the property due to unpaid taxes from 1980 and 1981. An agreement was later worked out as the owners promised to pay the back taxes. Meanwhile, the Shenango Valley School of Business began renting – and holding classes in – the main office building of Johnson Bronze along South Mill Street.

In addition to the tax battle a host of city, county, and state officials, alarmed by possible toxic contamination at the site, began pushing for federal inspections. A nasty legal battle ensued as city officials, the owners of the property, and former officials of Johnson Bronze fought to establish who was responsible for the cleanup. In March 1985 the city finally seized the property due to the unpaid taxes. In lieu of attempting to sell the property, it was put into a trust for the time being.

Finally, in late August 1985, the U.S. Environmental Protection Agency (EPA) conducted an inspection of the site and determined it to be of concern. The preliminary findings revealed, “An emergency assessment by EPA reveals the presence of extremely incompatible hazardous wasted stored in close proximity to one another and whose containers were in a state of deterioration; inadequate site security; and vandalism as evidenced by smashed lab jars with their containers mixed.” About 150 large drums were found on the property containing acids, cyanide, or other hazardous material. Soil samples revealed the presence of lead contaminants. The city hired the NUS Environmental Corporation of Pittsburgh to perform an environmental impact study. Multiple monitoring wells were drilled to test the groundwater, which showed elevated levels of contamination with lead and certain chemicals contained in cleaning solvents. The property, a major health hazard, was boarded up while further assessments continued.

An 8.3-acre portion of the Johnson Bronze site was soon designated for “Superfund” status, a federal program – officially known as the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) of 1980 – designed to clean up locations severely contaminated with hazardous substances. However, the site was given low priority and due to a lack of funding the cleanup was placed on hold. Meanwhile, the issue of groundwater and soil pollution also became a hot topic. It wasn’t until September 1989 that the EPA allocated $979,820 for the cleanup of the Johnson Bronze site. These funds were strictly designated for “above-ground toxic material” only, and not to be utilized for cleanup of the soil (groundwater) contaminants or the demolition of the buildings. The cleanup began on Tuesday, September 19, 1989, and progressed slowly and stretched into the summer of 1990.

In March 1990 the county officially purchased the property from the trust for $2,002 and conveyed it to the city, which began efforts to transform it into an industrial park. On Thursday, June 14, 1990, Pennsylvania Governor Robert P. Casey held a brief press conference at the site and presented city officials with a check for $760,000 to commence with the demolition of the buildings. The New Castle News of the next day reported that Casey said, “Beginning today, we can stop talking about the Johnson Bronze site in the past tense – instead we can talk about the opportunities for economic growth that this site provides.

In September 1990, once the EPA cleanup was completed, the city began accepting bids for the demolition of the buildings. Beaver Valley Demolition of Aliquippa was awarded the contract and was eventually paid about $293,000. The demolition commenced in November 1990 and took about eight months. The only building left intact was the main office building, which was still occupied by the Shenango Valley School of Business.

In the early 1990’s the city attempted to attract several possible tenants for its proposed industrial park, but it was difficult while efforts continued regarding the cleanup of the soil. The officials of the Arkansas-based Wal-Mart Stores Inc., who eventually opened a Walmart Superstore in Union Township in December 1995, were even approached about acquiring the property. Meanwhile, in late 1994, the removal of four 4,000-gallon underground storage tanks, each half-filled with contaminants and harmless sediment, was undertaken.

The cleanup of the contaminated soil was finally funded and authorized in early 1995. The New Castle News of Thursday, March 30, 1995, reported, “Decontamination of the former Johnson Bronze site is expected to take less than three months, and a city development official is optimistic that the property then will be ready to meet new industrial prospects… The operation involves removal, stabilization and disposal of soils containing elevated levels of lead and polychlorinated biphenyls, and backfilling and grading of the excavated areas. Groundwater contaminated with volatile organic compounds will be treated… The contracted company, Autumn Technical Services of Warren, Ohio, began soil sampling March 13. The work is being done in 20-foot intervals and involves removal of soil to a maximum depth of five feet. The potentially contaminated soil on the property will be stabilized with lime and then will be taken to the Browning-Ferris Industries Inc. landfill in Poland Township, Ohio, for disposal.”

By the end of 1995 various state and federal environmental officials deemed the former Johnson Bronze property ready for redevelopment. During a press conference held on Tuesday, May 21, 1996, Mayor Tom Fulkerson announced the site was being renamed as the New Castle Commerce Park. The next day’s edition of the New Castle News quoted Fulkerson with, “That area has been a problem for the city for so long that mention of the name conjures up nightmares. We are about to take the old site and bring in new investors, new businesses and new jobs… We feel that a new name would eliminate the stigma associated with the place.” During the summer of 1996 the city spent almost $105,000 to have tons of fill dirt dumped at the site.

On Thursday, July 17, 1996, Pennsylvania Governor Tom Ridge visited New Castle and one of his stops was at the former Johnson Bronze site. He brought a state check for $750,000 to assist in the continuing redevelopment of the site. During his stop a symbolic groundbreaking was undertaken by owners of several companies expressing interest in relocating to the location.

In 1994 the Shenango Valley School of Business vacated the former office building, and it was shuttered. The idea of renovating the structure was under discussion for some time and grant money was used to undertake an inspection. In January 1996 it was announced the plan was being abandoned and in early 1997 bids were accepted for asbestos removal and demolition. The building was cleared away a few months later. The main building of the Johnson Bronze plant No. 2 along Mahoning Avenue was occupied by the Nelson Group, a maker of wooden pallets and skids.

Businesses slowly gravitated to the improved site. In late January 1997 two businesses, D’Vron Ceramic Studio and Rocca’s Italian Foods, purchased several acres and began plans to build. D’Vron Ceramic Studio, a manufacturer of custom china products, was likely the first company to break ground in the fall of 1997. The co-owners and many of the workers were formerly employed at Shenango China, which closed its doors in 1991. Rocca’s Italian Foods, specializing in producing pasta, was close behind. Both were opened in late summer of 1998. In the coming years additional companies opened facilities in the New Castle Commerce Park, including Linton Industries, Richardson Cooling Packages, Huston Group, and Castle Maintenance Products.

Johnson Bronze, a longtime mainstay of the South Side, and the Flaherty family are both fondly remembered for their proud history of manufacturing quality products for the automotive industry.

To read about the company adopting the name Johnson Bronze in 1916 click on: NAME OF CONCERN IS CHANGED ARTICLE. To read about the expansion effort began in 1916 click on: EXPANSION ARTICLES. To learn more about the plant employing women in its skilled positions beginning in 1918 click on: TO EMPLOY WOMEN IN PLANT HERE ARTICLE. To read about the woman employees of the company marching in a Red Cross parade in May 1918 click on: JOHNSON BRONZE GIRLS COLLECT $26 ARTICLE. To read two articles about another expansion began in 1920 click on: NEW EXPANSION ARTICLES. Accidents involving employees at Johnson Bronze seemed less frequent then at other local plants. To read about a heroic effort to stop a potentially major fire at the plant in early 1923 click on: FLEMING PREVENTS DISASTROUS FIRE ARTICLE.

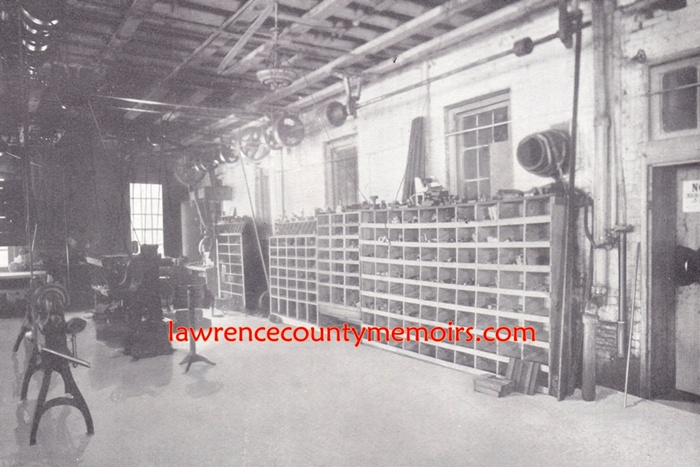

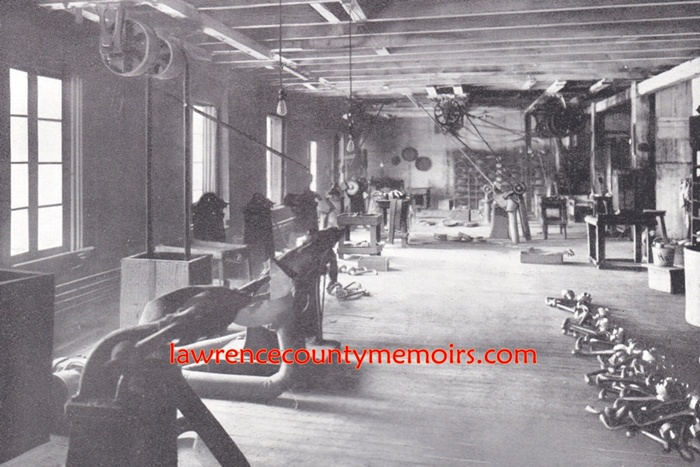

The American Car & Ship Hardware Manufacturing Company, which made brass and bronze fittings for trains, trolleys, and ships, was organized by industrialist George W. Johnson in New Castle, Pennsylvania, in 1901. It started with fifty employees working out of this one-room factory on South Mill Street. Full Size |

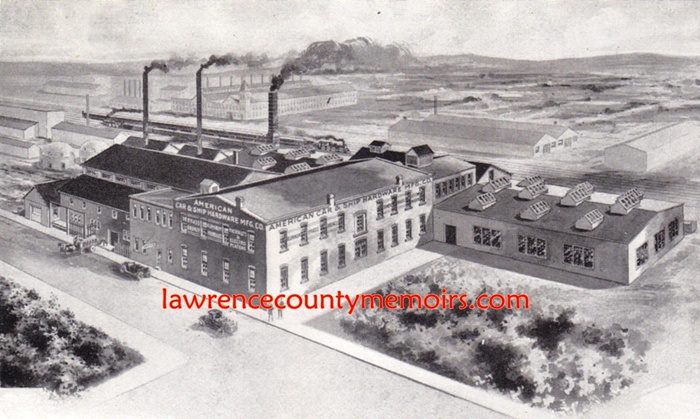

A view of the American Car & Ship Hardware Manufacturing Company, founded by limestone magnate George W. Johnson in 1901. (c1910) Full Size |

|

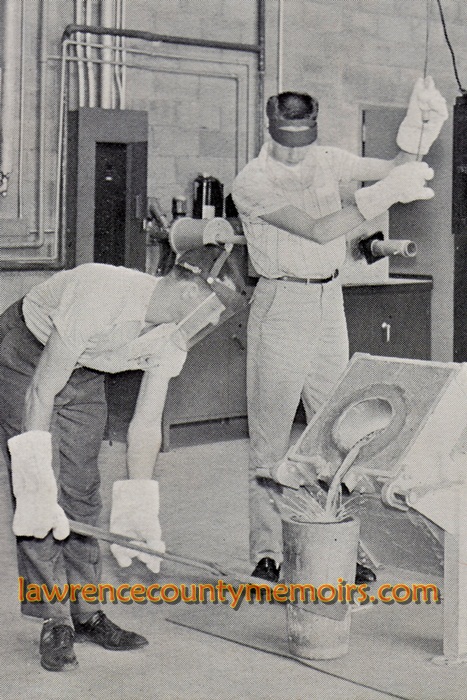

The caption for this photo reads, “It is in the foundry that the various blends of alloyed metal take shape in the form of castings.” (c1912) Full Size |

|

The machine shop of the American Car & Ship Hardware Manufacturing Company. (c1912) Full Size |

|

|

The plating room of the American Car & Ship Hardware Manufacturing Company. On page 22 of a 1913 company catalog I have it reads, “The sole thought in this organization is to give satisfaction, and it is being lived up to throughout the plant.” (c1912)Full Size |

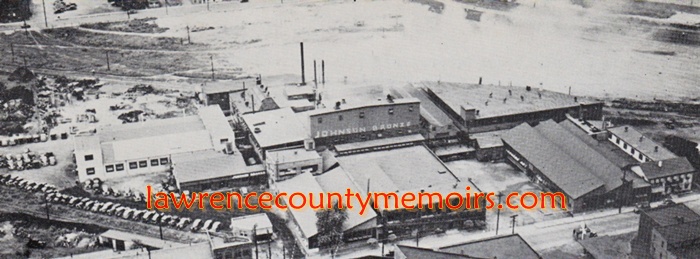

An overhead view of the Johnson Bronze facilities in New Castle in 1937. Full Size |

The Johnson Bronze Company, renamed as such in 1916, was founded as the one-room American Car & Ship Hardware Manufacturing Company back in 1901. The main plant, located along South Mill Street, grew considerably over the years. The inset photo shows the smaller facility established along Mahoning Avenue/McKinley Street in early 1951. Full Size |

Another map showing the various buildings of the Johnson Bronze Company along South Mill Street in New Castle. (1937) (Photo courtesy of Mitch Tannehill) Full Size |

A float of the Johnson Bronze Company takes part in a parade in New Castle. (c1950) (Photo courtesy of Mitch Tannehill) Full Size |

|

A new wing completed to the building that made bearings for the automobile industry. When completed it added 75,000 square feet of work space. (1948) Full Size |

This building was occupied by the Brass Shop, company hospital, and general offices. (1946) Full Size |

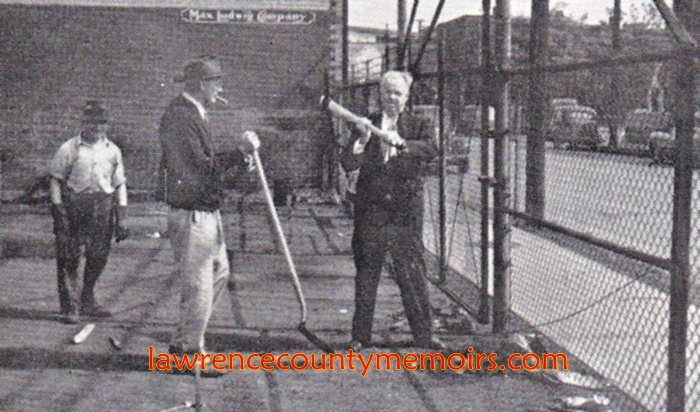

Company patriarch and Chairman of the Board P. J. Flaherty breaks ground for a new office building, shown completed in the next photo, along South Mill Street. Flaherty, who joined the firm back in c1909, was the guiding force of Johnson Bronze for almost forty years until his death in 1948. (1944) Full Size |

A photo of the completed office building along South Mill Street that housed various administrative offices of the company. (1946) Full Size |

Beginning in early November 1948 two representatives of the Glacier Metals Company of England, Fred Maer and William Anderson, undertook a ten-week visit of the Johnson Bronze facilities in New Castle to study production methods. Prior to returning home in mid-January 1949 the two men enjoyed a luncheon (shown above) at the Castleton Hotel with all the top executives of Johnson Bronze. (1949) Full Size |

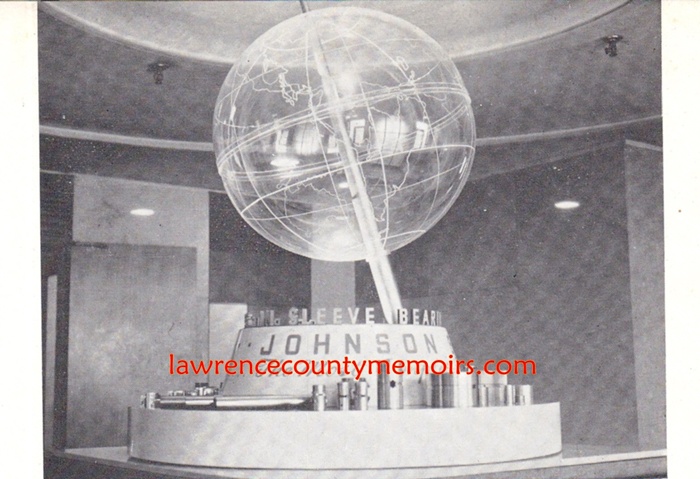

The plastic globe that graced the lobby of the main office building in New Castle. (1951) Full Size |

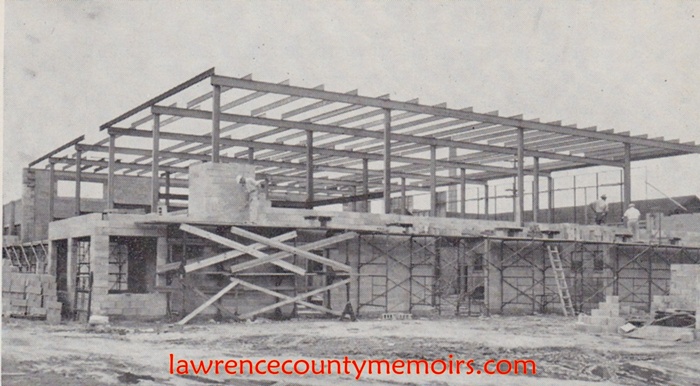

A new foundry under construction at the new JB location on Mahoning Avenue in New Castle. (1951) Full Size |

Longtime Johnson Bronze truck driver Burley R. Brown. (1951)Full Size |

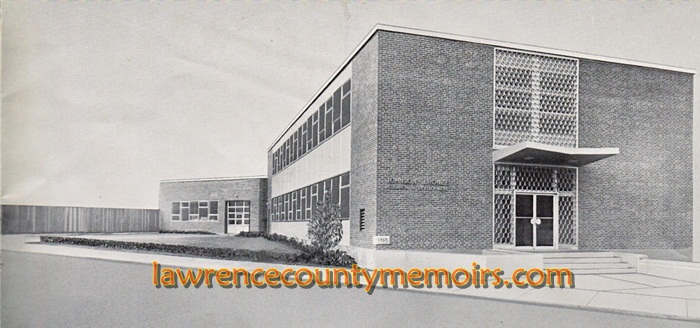

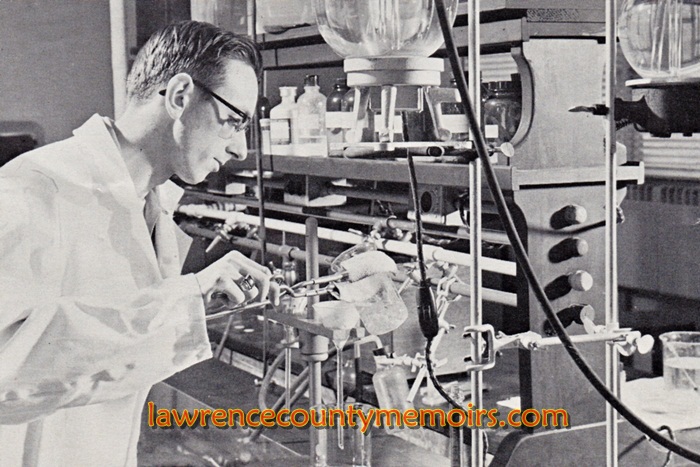

The new $500,000 Research Laboratory opened on South Mill Street in early 1959. It was modern facilities like this that helped make the company a world renowned leader in the production of bronze sleeve bearings and bushings. The company reportedly made sales in over sixty countries around the world. (c1965) Full Size |

|

The Johnson Bronze Company always seemed to be expanding and was constantly adding new facilities, such as the Oakland, California, subsidiary shown above. Nationally, the company had over thirty warehouses/sales offices and employed about 1,600 total workers at its peak. (c1964) Full Size |

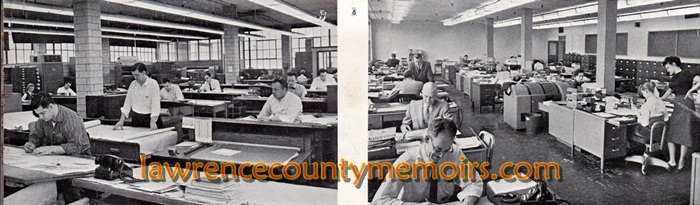

These photos show engineers at work in the drafting room and the administrative offices of the company. (c1965) Full Size |

These photos show men at work in a foundry and also a machine shop of Johnson Bronze. (c1965) Full Size |

|

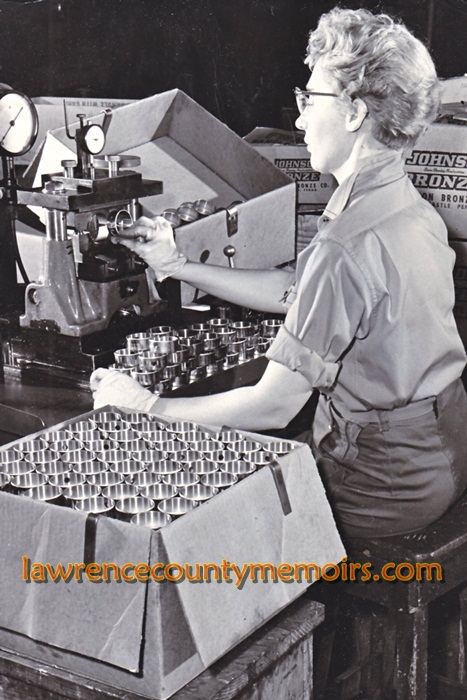

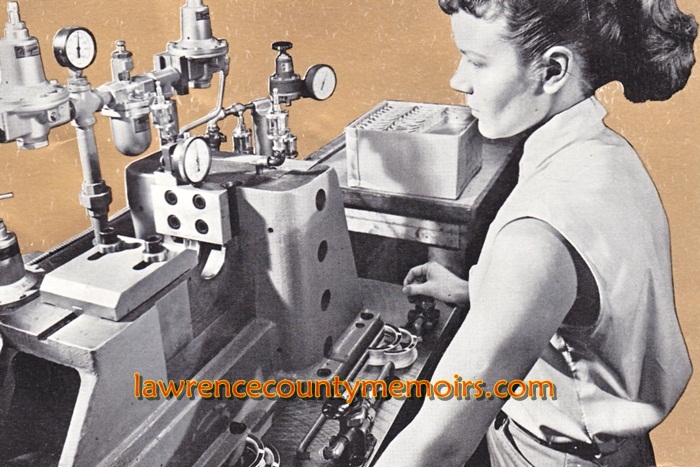

Employee Leona Nickum hard at work taking measurements. (Mar 1956) |  Another employee checks for the proper diameter of a large bearing. (c1965) |  Men at work in a foundry. (c1960) |

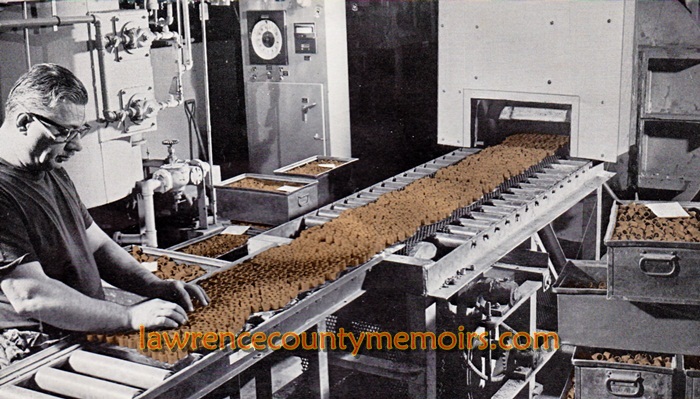

A worker checks sleeve bearings along a conveyer belt. (c1965) Full Size |

|

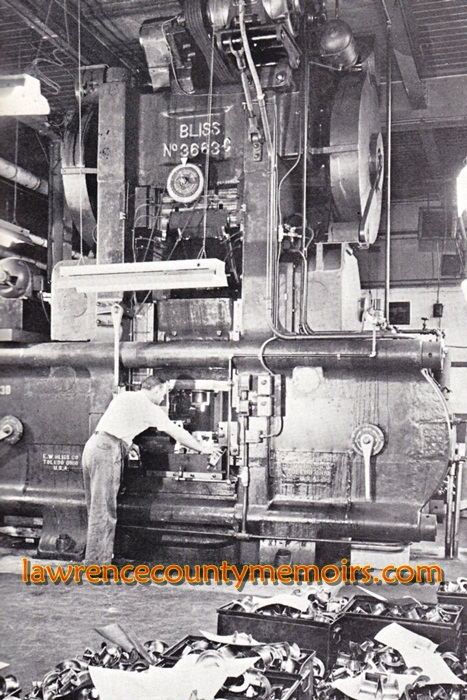

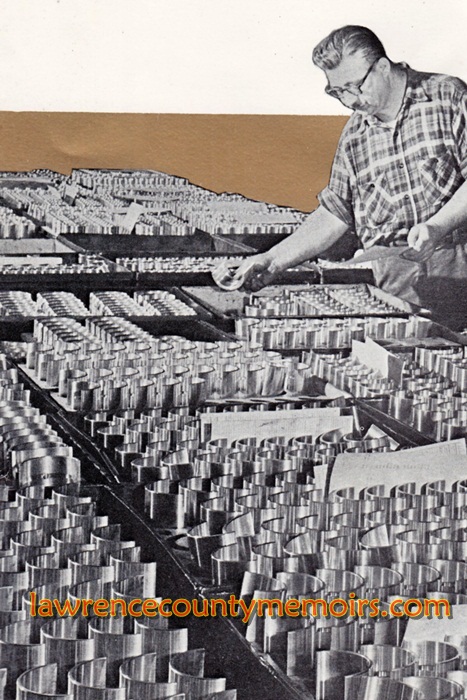

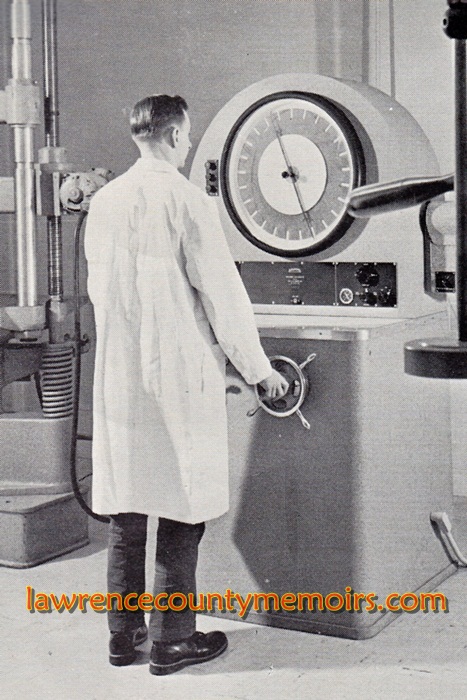

A worker operates a heavy-duty press machine. (c1960) |  A workers prepares bearings for shipment. (c1960) |  The quality control functions of the company are carried out in the Research Lab. (c1965) |

Two badges belonging to employees of the New Castle plant. Full Size |

Additional badges of Johnson Bronze employees. Full Size |

A small box that once held a product manufactured by the Johnson Bronze Company. |

An employee involved in quality control tests the crush weight of a bearing. (c1965) |  The composition of the various metals used for production are tested and formulated in the |

|

This photo depicts the barren spot where the Johnson Bronze admin building and other facilities once sat along South Mill Street. (Jul 2013) Full Size |

Former parking spots of Johnson Bronze executives at the rear of the Jefferson Poultry building. (Jul 2013) |  This weathered metal sign marks the former parking spot of Edward Flaherty. (Jul 2013) |

The sign for the New Castle Commerce Park, which occupies the former site of the Johnson Bronze complex, at the intersection of Moravia Street and East Division Street. (Oct 2014) Full Size |

Comments

Lyn Flaherty Goekel #

Hi, I am so thrilled to find this website today. I am awestruck by the amount of time and effort that you have put into this site. My father Edward Flaherty was president of the Johnson Bronze until it was sold in 1968. Prior to that hew worked for my grandfather Patrick Joseph Flaherty whow was president until his death in 1948. Thank you so much for sharing all of our hometown history. I am so tickled to find all things New Castle today. All the best ,lyn

Jeff Bales Jr #

(EDITOR’S NOTE) Lyn, thanks so much for your posting and the compliments. I’ll have the text and captions up for this page soon. Would you happen to have photos of your father and grandfather that I could use to post on this page? I would really like to share those with my readers. Thanks again. Jeff

Lyn Flaherty Goekel #

Hi Jeff, I am so happy to see The Johnson Bronze portrayed today. Needless to say you have done an outstanding job to show the evolving history . I am so appreciative of your endeavors to present the history of Lawrence County. Our hometown has such a rich history. The investment of your time and dedication is a testament to our hometown.

Kathy McNerney Darlington #

It is so exciting to read about Johnson Bronze. I have looked for information occasionally and it was great to read such such a thorough history of the company.

My grandfather was Joseph F Flaherty. I grew up

hearing about the company, I was thrilled to read about it!

Mitch Tannehill #

Hello Jeff

Great Job…

My Great Grand Father was PJ Flaherty.

What an outstanding job you have done.

I have many old photos of PJ Flaherty & of JB.

Plus a very large collection of Bronzes made by the Co.

Would love to share…

Thank You

Mitch

David Bean #

I am in procession of what may be a bronze ashtray in the shape of a housefly 5” long, 2.5” wide. The wing tilts up revealing a cavity possiblity for cigarette ash. Under the wing it’s labeled “Johnson Bronze Co. New Castle”

Was it common for them to also make household products and novelities?

Would you know when the housefly was made?

Thank you

Dave

Jeff Bales Jr. #

(EDITOR’S NOTE) David, I have seen a handful of these well-crafted bronze novelty items made by Johnson Bronze. All the ones I’ve seen have been ashtrays with statues, figures, etc… attached. One was a miniature Liberty Bell. I have never seen any evidence that JB sold these items commercially, so I’m thinking they were probably made exclusively for employees as achievement-milestone-retirement gifts. I’ll try to do some more reasearch on this matter. Jeff

Dennis Holtz #

My father Elmer M. Holtz worked for Johnson Bronze Company in the Chicago office in sales all his life until his retirement. He always told me about the great respect he had for the company. I am now 70years old and still have the liberty bell ash tray and a bronze light that looks like a bird. Those were the days your worked hard and stayed with one company until retirement.

Thank you,

Dennis Holtz

Dennis Holtz #

My father Elmer M. Holtz worked for Johnson Bronze Company in the Chicago office in sales all his life until his retirement. He always told me about the great respect he had for the company. I am now 70years old and still have the liberty bell ash tray and a bronze light that looks like a bird. Those were the days your worked hard and stayed with one company until retirement.

Thank you,

Dennis Holtz

dennisholtz@yahoo.com

slack #

nice site, to any one what year did this co close its doors

George George #

I have an amazing ash tray by this company, it;s a bronze man hold a smelting pot pouring into a square box of sorts, signed Johnson Bronze Co. About to go on ebay.

David Boatman #

My father was employed at the Johnson Bronze for many years, working his way through the Engineering department and up the ranks to become a Vice President. Tom Acker, another VP at the Bronze was a close personal family friend and still is. It’s nice to see a site dedicated to the Johnson Bronze. I remember going to the Scottish Rites Cathedral as a child with my brother in the late 1950’s for the Bronze’s Christmas show and event. They gave all the kids giant red mesh stocking filled with toys and candy. Fond memories.

Nick Mitlo , Jr #

Again, I am just blown away at your web site on New Castle! My father worked his way up in the Johnson Bronze organization. He started on the pouring gang in the early 30’s and later went into making the molds. In the early 1950’s he was transferred to the operation in Mahoning Town and assisted in supervising production. In October 1957 he was transferred to manage the production work at the new Oakland CA location. That facility closed after a few years due to high labor costs in California. Most all management went back to New Castle but he loved California so much he decided to stay after almost 40 years with the JB.

THX for such an excellent effort on your part.

PJ Flaherty III #

We have some nice pieces from the JB, the liberty bell, a scale, and one of the massive PJF memorial bronze plaques, among other things, including PJF’s manuscript (partial) biography. Can send pics. Nice site, thanks for the effort!

PJF3

sally patterson #

Wow. I am shocked at this wonderful website. My dad’s family was from New Castle. His mother and father raised their family there and my grandfather commuted to Pittsburgh via the train every day. My grandfather was James Patterson and my grandmother Grace Leslie married in the late 1800’s. I have relatives that worked at Johnson bronze and the way I found this site was by searching for these bronze ashtrays. Per my father, his brother received the ashtrays as a Christmas gift. I too have the liberty bell, a wheelbarrow, a naked lady and a soldier. I still have cousins that live in the Area. You mentioned Cascade Park in you biography…my aunt Sally (my namesake) was Sally Glenn, daughter of Billy Glenn. Billy Glenn was the creator of the roller coaster “the Gorge” in 1922. My aunt told us many stories of living at the park in the summer under the roller coaster….Billy had built a summer home for his family there.

Many thanks for this great forum.

Arnold Edward Fraser #

My father Bud Fraser a mechanical engineer, spent his whole working career at the “Bronze” before and after the war as did most of my aunts and uncles. Dad was a Foreman for many years and later the Plant Manager & also Personnel Manager. He admired and was close with the Flaherty family particularly Press.

Interesting side note – my uncle John Fraser (Dad’s brother) was head of the Union. We had many family gatherings at our small farmette with all the family coming out for picnics nearly every other weekend. Almost every time my uncle and Dad would go round and round with my Dad trying to convince my uncle that if the union persisted with “strike” plans that they would have to close the plant. My uncle insisted that they weren’t being shown the “real” books – but were being shown “cooked” books regarding finances. He was very stubborn and wouldn’t listed to reason from Dad. They were on opposite sides of the barganing table and Dad proved correct when the Bronze was forced to sell out and the new owners layed everyone off and sold off the pieces of the Bronze. All my family lost their jobs. Dad ended up with a pension of $150/mo. after more that 30 years there. Sad really.

Richard Kovacs #

My mother worked at J-B in New Castle during WWII. She said the female workers were impressed with the handsome German POWs that were brought in under armed guard, evidently to work in another area. I am curious how and why this program was instituted.

Jeff Bales (EDITOR) #

(EDITOR’S NOTE) Richard, During World War II over 400,000 German and Italian POWs (or simply “POW”)were interned in the United States. To augment the depleted workforce many of these prisoners were approved for “off post” projects such as working on large farms or at industrial factories. A total of 1,868 German POWs were housed at Camp Reynolds in Mercer County, or four outlying camps. A handful of these Germans worked in New Castle at the Johnson Bronze plant. It’s no secret that the local woman fraternized with these “handsome” German soldiers on occasion. Jeff

Kathy Dudash #

I was so happy to see this! My father worked there for years! All I remember is, he was either a machinist or tool and dye maker. He got hurt, and they made him a security guard. I still have his badge. His name was William Callahan. Thank You for the memories!

Carolyn Dute Davenport #

My dad, Ralph Dute, worked there for many years in the 1940’ s until he retired. The only job he ever had besides being a butcher. Thanks for the memories!

Larry Ciambotti #

Jeff:

Old photos of Johnson Bronze brought back sweet memories.My grandfather and father owned and operated a bakery and restaurant @ 423 S. Mill Street directly across from the J.B.I can still remember the employees patronizing the bakery and restaurant.When strikes persisted in the mid to late fifties,my father decided to sell and moved to Sharon,PA to pursue another opportunity. Thanks again for the memories!

Mildred Shaw #

Iam especially pleased to see this for the first time and want you to be able to put a name to the young man in the Quality Control

Lab in the white coat: His name is Jack Shaw

and loved the 13 years he worked at the Bronze.

However, when the layoffs began he did not have enough time in to receive any compensation. His cousin, Carol Sanner Putnam, now in the Carolinas married Mike Flaherty and I don’t know for how long. Jack Shaw loved them both dearly and Jack was asked to be the overseer for Mike. Jack passed away March 27, 2014 and I am not quite over it. He is the only man in the long white coat in two of the pictures. Three hundred attending the funeral and more would have but it had to be done quickly for various reasons. Thank you so much for all of your hard work and the heart you have put in it. We still keep in close touch with Mike Flaherty’s ex-wife in Hilton Head.

Cheryl Glaxner #

Dad (Jim Glaxner) worked for the JB in the tool crib from the early 40’s to the middle 60’s. As a little girl I remember the fun times the company provided for us twice a year. Family day at Cascade Park with free rides and hotdogs in the summertime and at the Cathedral for the annual Christmas day for kids showing movies, live entertainment and finally Santa with a small gift. Two very special days growing up as a child in New Castle.

Frank Cellucci #

My dad worked for Johnson Bronze Company after service in WWII in the US Navy. He was the warehouse manager of a branch located on Belfield Avenue in Philadelphia for over 25 years. It was a three person operation, a salesman, a machinist and my dad who was responsible for everything, inventory, shipping, receiving, customer service, you name it. I have fond memories as a young boy going to the warehouse with my dad to count inventory in advance of the company’s auditors visit. Sadly, the warehouse was relocatd to South Hackensack, NJ and after a year of commuting and training a new manager he left the compnay rather than relocate our family. He remembers meeting one of the Flaherty family members who visited Philadelphia. I reviewed this website with my dad yesterday, now 87 years old. Thanks for creating this site. Dad really enjoyed it.

Terry Dudash #

One of the Flahertys wrote a biography??? Is that correct. I would LOVE to read it. I worked there from 1976 till JB went under in 1981. I even worked for the auctioneer for a short while. That was sad, because I really liked working there. I was the youngest machine setter (at 24) on the chamfer machines and the semi-progressive dies. My boss was John F McConnell who also became my best friend. Super guy !!

Lou Delpha #

Nick Mitlo, My father worked with your dad Bill at Johnson Bronze. I remember meeting your dad over at our house. He was a very nice man and a good friend to my father.

Carol Lee Palumbo #

I never met my Grandfather Frank Mundziak aka Mundziakiewicz, but he worked at JB until he died of lead poisoning in or around 1940. My mother had a beautiful collection of the bronze figurines. Many were stolen when our house was broken in to, but, I have spent many years searching for as many JB figurines as I can find. I am still searching for the one that was my favorite; a DOG NUTCRACKER…If anyone has one that they would part with, please, PLEASE let me know. My mother is almost 84 and I would love to give her that special piece before she is gone. Thank you for this wonderful site !!!

Diane Eakin #

Can you please give me information on the bronze foundry sculpture od a man pouring steel. I have acquired 2 from parent’s estate. I have seen them online auction for $395.

Any information would be appreciated.

Thank you

Diane

Eakin

Barbara (Basta) Liberato #

I met a Michael Flaherty at WPIC circa 1962. His family was connected to Johnson Bronze Co. of New Castle. Would be interested in re-connecting

David Parsons #

Both of my parents worked at the JB. My mom Millie Peterson was a machinist in 1942-43 & met my dad Dave Parsons a machinist, inspector, & later salesman for the JB. My father worked for the JB from 1940-72. As a family of 6, we The Parsons were born & raised in New Castle until my Dad Dave Parsons was given the opportunity to move to the Oakland, CA Johnson Bronze warehouse & was made Headsalesman for the West Coast. It was always fun going to the Xmas parties at the Cathedral & having pancake breakfasts & the toys & candy in the stockings. In the summer the JB would have picnics at Cascade Park & give tickets for rides. It seemed like every year in the late 50’s & early 60’s they would go on strike in late Nov.-Dec. We would eat Navy beans & Kraft cheese during those times. The JB really never paid their workers an adequate salary. My dad went to night school via Penn State & took engineering & architect courses to improve himself. My father knew Jack Flaherty & spoke highly of him. My father Dave Parsons died here in Walnut Creek! CA in 1978 at the age of 57. My mother Millie Parsons is 94 & lives in Walnut Creek. I am David Parsons Jr. My brother Bill Parsons, sister Joyce, & sister Yvonne live in Walnut Creek or nearby cities in CA.

Andrew Butchko Jr #

I grew up in Western Pa & have a nice collection of the JB figurines !

1 Steelworker pouring steel with box underneath 2 catch molten steel

2 Wheel barrow

3 Cricket/Fly with internal space 4 storage

4 Venus De Milo with ashtray

An EBAY seller from New Castle has available 4 sale the:

Steel worker; Cricket; Statue of Liberty (W/O ashtray; Lion head astray & large Dachshund 2 piece bookends.

Another EBAY seller has a set of JB “Bust French Beatrice” bookends.

I have never seen the “Soldier:; “Scale” or the “NutCracker” but I will keep looking.

I love them !

Good Hunting !

Carol Kubala #

Recently, I discovered that many members of our family have wheelbarrow ashtrays. I thought I was the only one to have one of these. In doing research about them, I also discovered that many others in my hometown of New Britain, CT also have wheelbarrow ashtrays dating back quite a few years, possibly the 1920’s or 30’s. We now wonder if they might have been purchased by a New Britain Company and were given to their employees. None of those that we have include any markings to indicate the maker. I noted that some of the ashtrays mentioned here do have the JB name. Do the wheelbarrow ashtrays include these markings?

I have been unable to find any connection between JB & Connecticut other than Charles H. Schubert being brought in from CT to serve as president. There was a company in Waterbury that made brass items that had Johnson in their name.

Andriy Gretskyi #

Hello

I would like to offer for sale domain name bronze.company which was registered on 05/2020 This domain name already attracts visitor traffic which will be useful to grow online exposure of your business. This domain name will allow convenient and effective advertisement of services for all global locations of the company. The .company domain is gaining popularity among companies with well-known trademarks and large customer bases. Consider to own the bronze.company domain name for a website representing your business online.

Sincerely Andriy Gretskyi

Alan Puromaki #

I was hired as a quality control technician, right out of high school in 1964. Worked there for a year before I was laid off. Great memories of the place and the people.

Comment